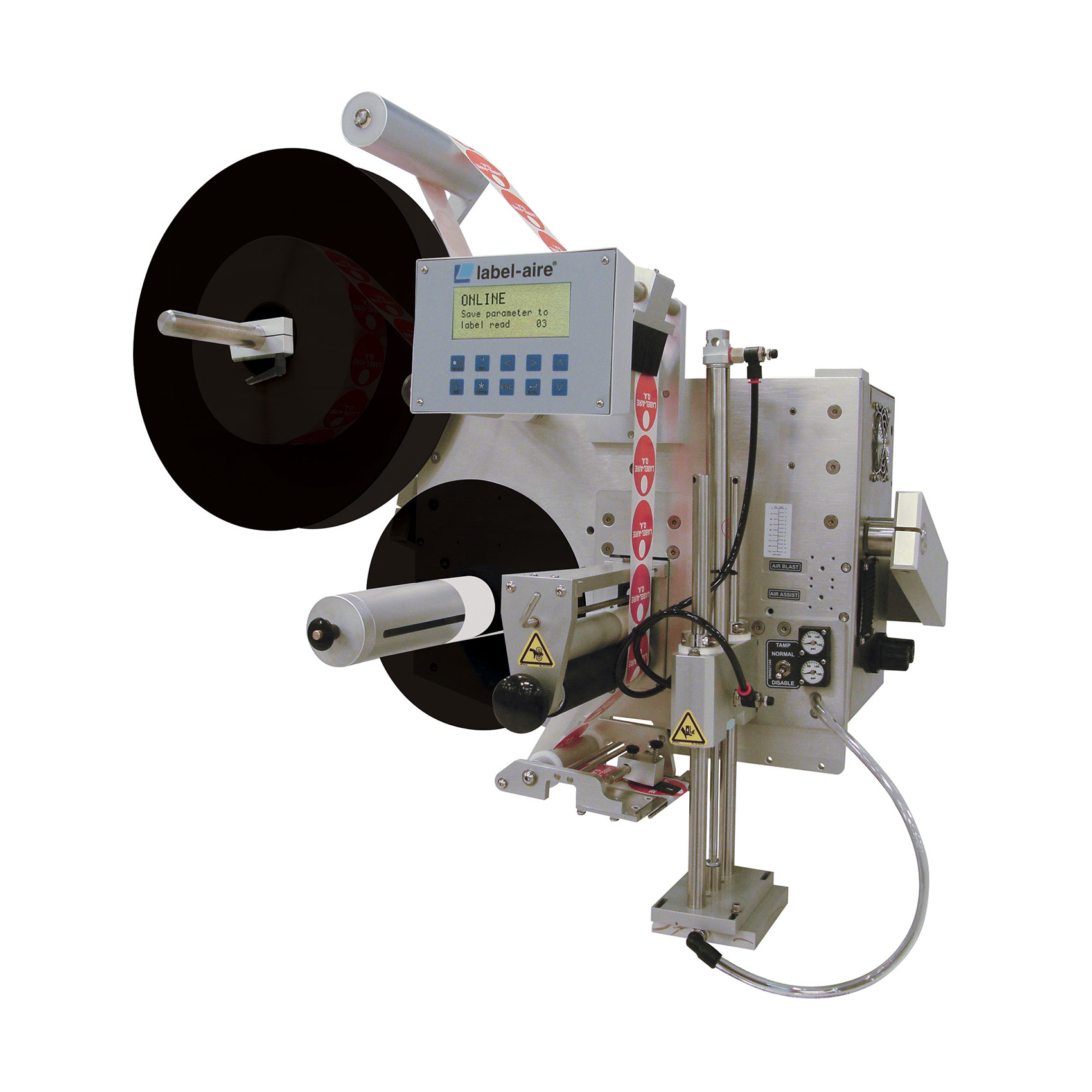

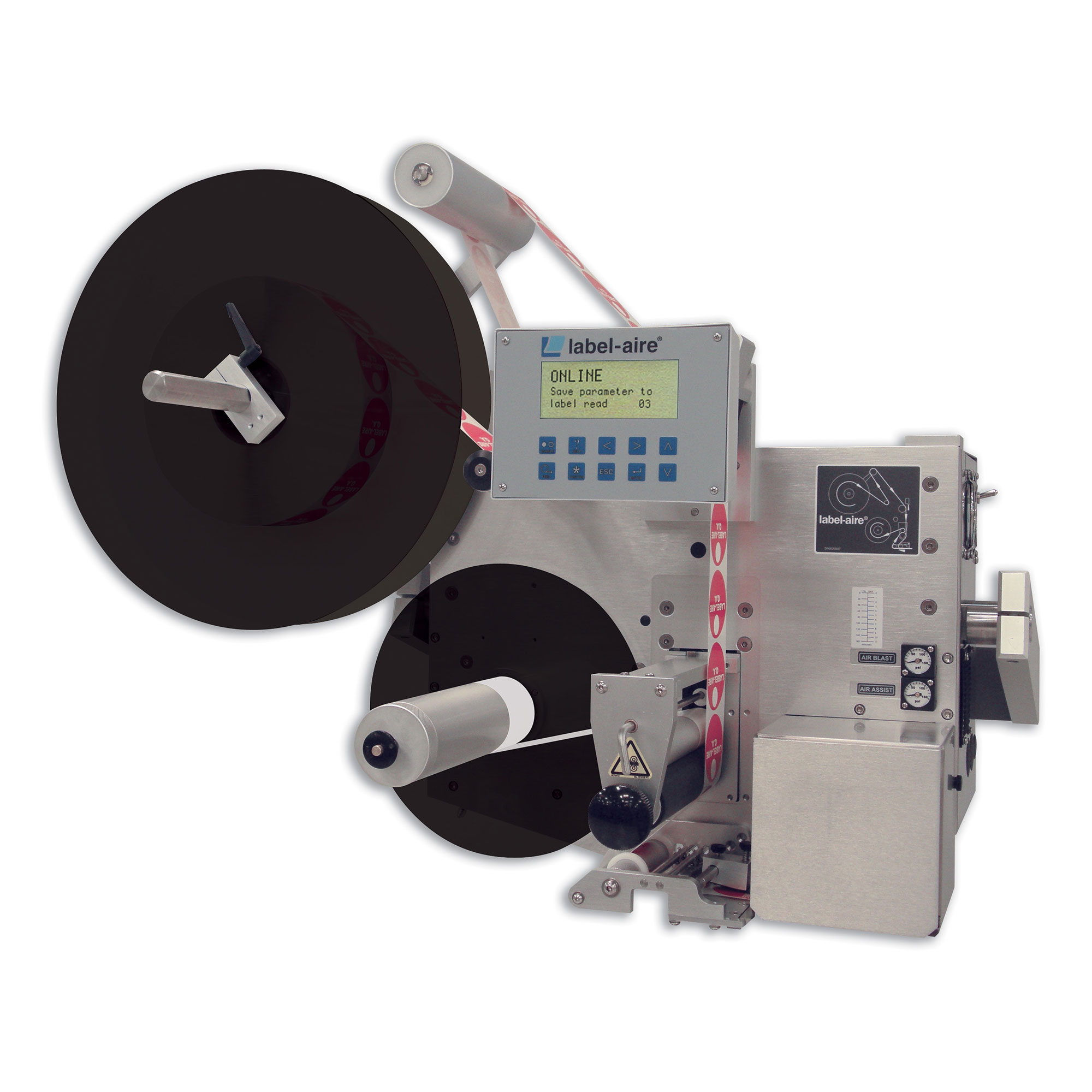

3114-NV TAMP-BLOW PRIMARY APPLICATOR

The NEW Pacific Labeling® Model 3114-NV makes labeling easier and faster…making you more profitable.

The Model 3114-NV Tamp-Blow labeler delivers on its promise of speed, accuracy, and ease of use. And that translates into lower operating costs and increased productivity for your business.

The Pacific Labeling Model 3114-NV was designed for high-speed tamp-blow labeling applications at a standard dispense speed of up to 1,500″ (38.1 m) of web per minute or up to 2,000″ (50.8 m) with the optional powered rewind. Advanced features include Velocity Compensation for improved label placement accuracy, a microprocessor controller with digital display, and ambidextrous parts. Zero Downtime Labeling allows your production to continue without costly interruptions. Missing label compensation virtually eliminates unlabeled products. Furthermore, the 3114-NV comes standard with a heavy duty double stack stepper motor-at no extra charge as well as a standard 1″ to 10″ (25.4 mm to 254 mm) adjustable stroke. Not only can the 3114-NV be easily converted to left- or right-hand use, it can also apply labels to the top, side, or bottom of products with a label dispense accuracy of up to +/- 1/32″ (.8 mm). Adding to the 3114-NV’s versatility are the availability of air-blow and wipe-on conversion kits.

Put this tamp-blow pressure-sensitive technology to work for you all day, every day. The Model 3114 Tamp-Blow labeler is built to meticulous quality standards and designed to withstand the most demanding operation.

3114-NV Tamp-Blow Advanced Features

| Automatic setup |

Includes multiple programmable label pages for easy changeovers to different label sizes. |

| Standard adjustable stroke |

1″ to 10″ (25.4 mm to 254 mm) |

| Stepper motor drive |

For precise starting/stopping, increased reliability, wider range speed variability, and lower maintenance. |

| R3 digital display |

Select from five languages (English, French, German, Italian, Spanish), domestic or CE (European) configurations, standard/metric unit display and detailed alarm messages.

Can rotate 360°in 90°increments. |

| Velocity Compensation |

For improved label placement accuracy. |

| Optional quick-action collapsible rewind |

Allows easy removal of scrap liner. |

| Optional smart powered rewind |

For dynamic web tension control. |

| Tamp-blow applicator |

Easily adapts to air-blow or wipe-on use. |